38 electrical panel labeling standards

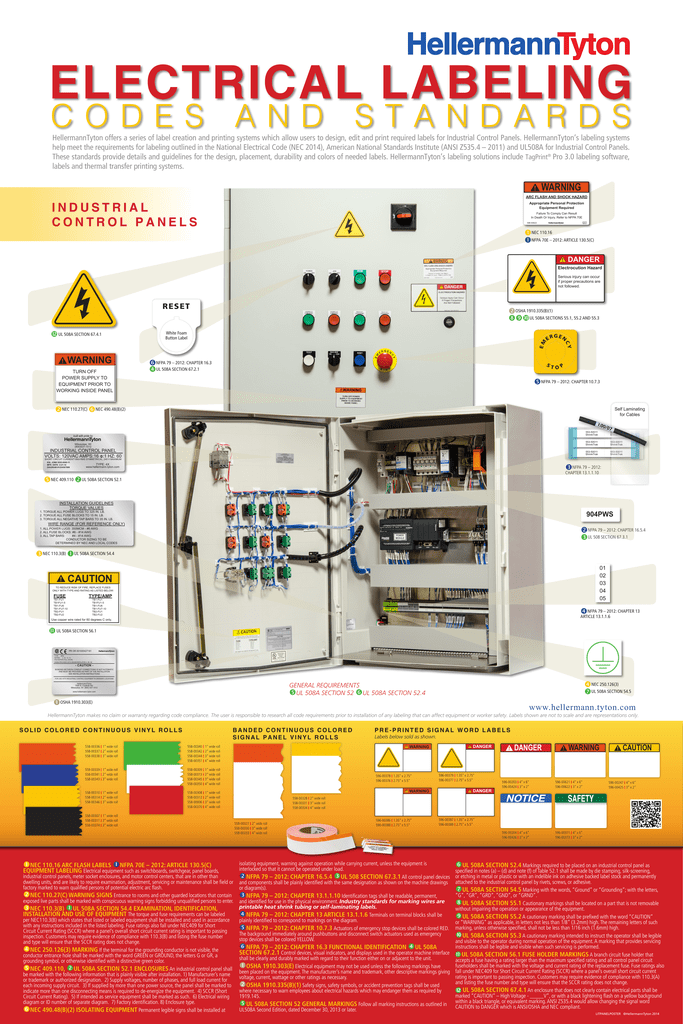

1910.303 - Occupational Safety and Health Administration In all cases, the working space shall permit at least a 90-degree opening of equipment doors or hinged panels; and 1910.303 (g) (1) (i) (C) The work space shall be clear and extend from the grade, floor, or platform to the height required by paragraph (g) (1) (vi) of this section. OSHA requirements for warning signs and protection from electric-arc ... 1 Section 400.11 of NFPA 70E-2004 states: Switchboards, panelboards, industrial control panels, and motor control centers that are in other than dwelling occupancies and are likely to require examination, adjustment, servicing, or maintenance while energized shall be field marked to warn qualified persons of potential electric arc flash hazards.

NEC Changes Part I: Required on Electrical Disconnect Label Anything beyond a visible conduit to a local load indicates a clear cut need for proper labeling of the disconnect. The "identification of the source that supplies the disconnecting means" is a critical addition to the 2020 NEC. For ALL disconnects, the associated power supply must now be clearly indicated on a label that is legible and clear!

Electrical panel labeling standards

A related requirement is NEC 210.5 (C) (3), which defines the labeling of conductors originating within each branch circuit panelboard or similar branch circuit distribution equipment. The wires need to either be color coded or marked with color-coded labels. Example: A = black, B = red, and C = blue (neutral is white) PDF Electrical Electrical Identification Basis of Design Label conduit at all wall penetrations and connections to all panels, junction boxes, and equipment served. 3. Use a black indelible marker and hand print label in a clear workmanlike manner, or use stencil and black paint to provide a clearly legible label. C. Empty conduits 1. OCWR - Electrical Panel Safety For equipment operating at 600 volts, nominal or less to ground, electrical panels must have a minimum of three feet of clearance in front of the panel and a minimum clearance width of 2.5 feet or the width of the equipment, whichever is greater.

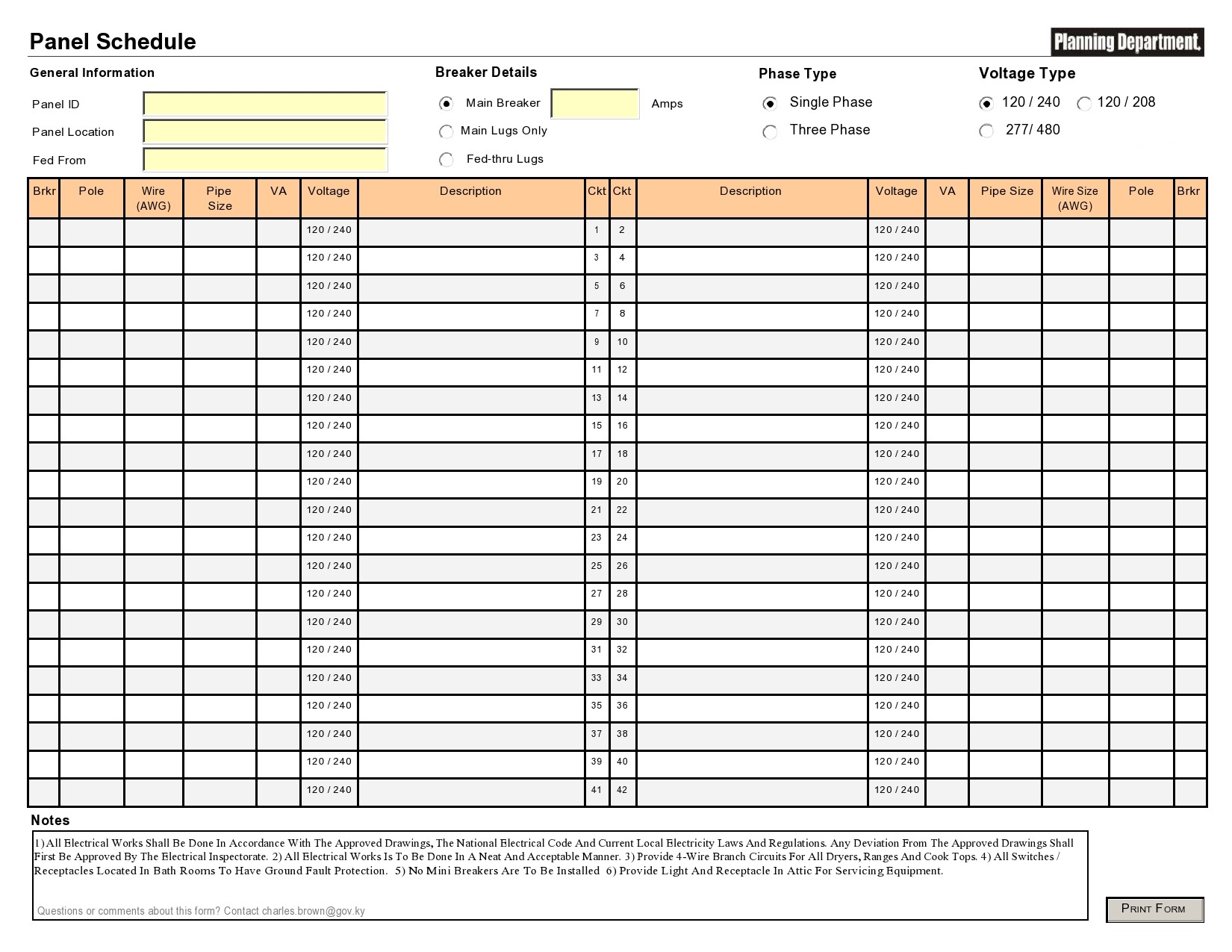

Electrical panel labeling standards. If your industrial control panel is installed at the point of entry for the electrical supply circuit, the panel must be marked "Service Entrance Equipment" per the International Electrotechnical Commission (IEC) "EN Standard EN60 204-1 (2)" and NEC Art. 409. What are the Requirements for Labeling Circuit Breakers? If you remove a breaker because it is no longer being used, you need to update the labeling to reflect that. You should not have an empty breaker slot with a label to the side. Instead, that label should be removed or a blank label put over it. Another similar issue is when there is an opening in the box that no longer has wires going through it. PDF NFPA 70E LABELING REQUIREMENTS - ese-co.com The NFPA 70E Standard provides guidelines for electrical safety in the workplace. This standard has been updated ... The only exception to these new label requirements is to allow labels applied prior to September 30, 2011 to continue to be used if they have the available incidence energy or required PPE listed. Electrical Panel Labeling - IEEE (electrical) Code Issues - Eng-Tips Is there a standard for properly Identifying electrical Panels in a Industrial plant enviroment? I am interested in Panels that are for voltages below 600 VAC. Engineering.com. Tek-Tips ... Electrical Panel Labeling. busbar (Electrical) 12 Jun 03 20:18. If the question refers to NEC384-type panelboards, switchboards, {and MCCs} it is trivial to ...

PDF Electrical Panel and Circuits, Marking - ResponsibleAg The markings must be of sufficient durability to withstand the environment involved. 29 CFR 1910.303(f) - All panel board circuits must be identified on the face or inside of the panel door. Each disconnecting means for motors and appliances must be legibly marked to indicate its purpose, unless located and arranged so the purpose is evident. Electrical Panel Location and Installation: Clearance, Bathrooms ... Electrical panels need to be installed 4′ off the ground with the center grip handle of the highest circuit breaker is no more than 6'7″ high to be NEC compliant. The clearance around the electric panel must be at least 30 inches wide with 3′ of front workspace clearance. The electric panel door must be able to open to a 90-degree angle. Arc Flash Labeling Requirements | Comply with 2021 NFPA 70E According to NFPA 70E, labeling is required for any piece of electrical equipment that may need examination, adjustment, service or maintenance while energized. These labels communicate the electrical hazards an employee may be exposed to, including the potential for an arc flash incident. Electrical Code - Circuit Breaker Panel Box Requirements Whenever electrical work starts, it's time to review the National Electrical Code (NEC). This code book explains the many rules and requirements, while also providing guidelines for safety. When it comes to a new or replacement breaker panel, be sure to get started by choosing a location that conforms to NEC code.

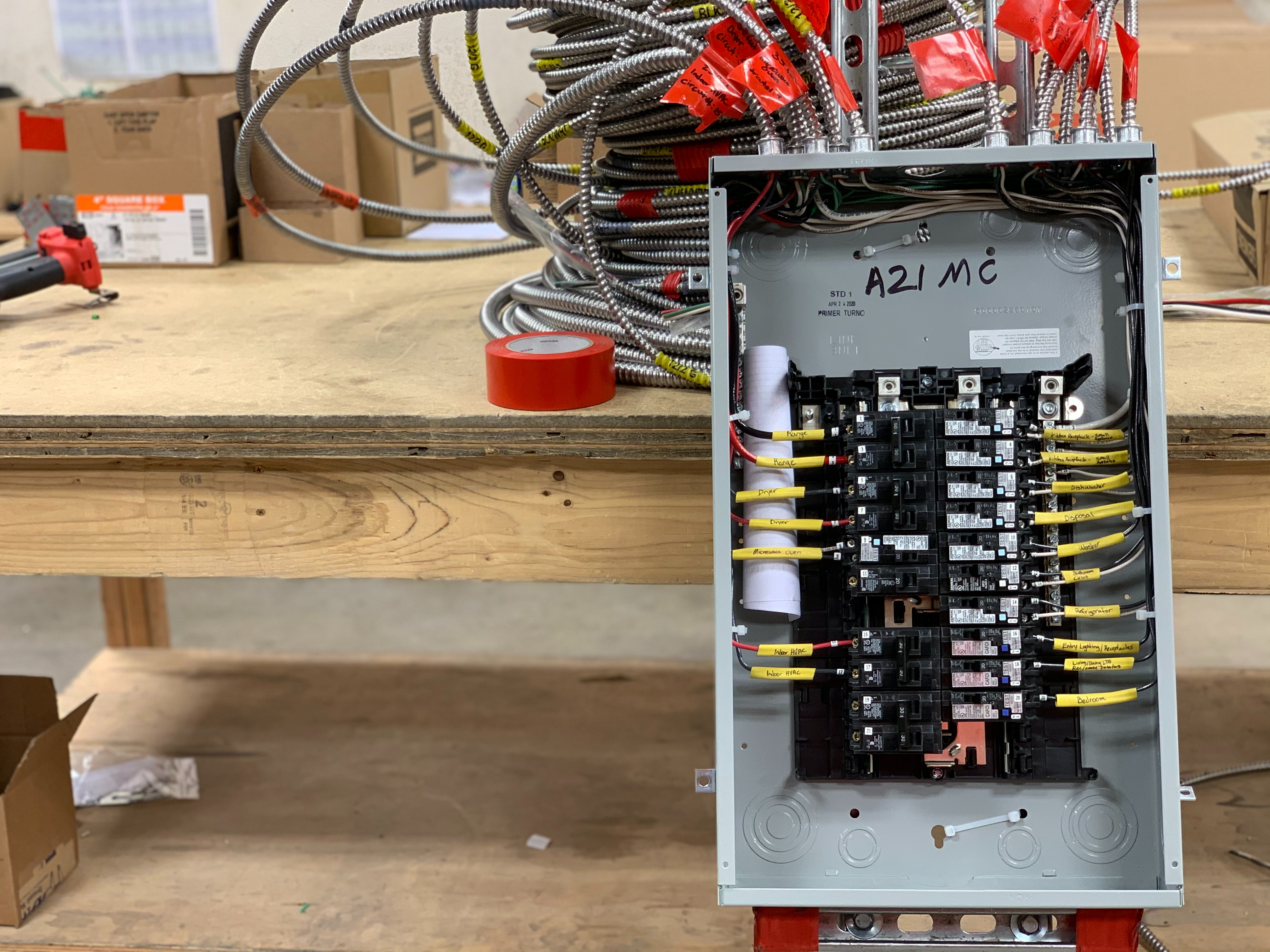

Service Equipment Labeling — NEC 2017 110.16(B) Figure 1. Arc flash hazard warning label as required by 110.16 (A) of NEC 2017. NEC 2017 introduced the new first level subdivision 110.16 (B) Service Equipment. This new addition applies only to service equipment rated 1200 amps or more. Note that this is the rating of the equipment, not the rating of the OCPD protecting the service equipment. How to label properly? | Electrician Talk Label the panels from top to bottom. Odds on the left (1,3,5,7......). Evens on the right (2,4,6,8....). Label the conductors at their termination point in the field the same using number tags. In residential, if there are tandem breakers, they are A&B for each corresponding breaker space. Complete Guide to Electrical Panel Labels - Metalphoto Of Cincinnati There are thousands of ANSI standards, but the one most important for electrical panel labeling is ANSI Z535 and specifically ANSI Z535.4 American National Standard for Product Safety Signs and Labels. ANSI Z535.4 4.11: "A symbol that indicates a hazard. It is comprised of an equilateral triangle surrounding an exclamation mark. Step by Step Guide to Labeling Your Electrical Panel — Multi Trade ... The simplest reason to label your electrical panel is that it is an Ontario Electrical Code requirement. The Electrical Safety Authority sets out a clear set of rules and policies to ensure the safety of the public. One of those rules is to have your electrical panel appropriately labeled. What you need to do this yourself

Electrician's Guide on Labelling an Electrical Panel - GforceElectric Labeling electrical panels is indeed important in ensuring safety and preparedness for any home electrical emergency. Gforce Green Electric Solutions 2920 McGraw St San Diego, CA 92117 (858) 480-6559 Gforce Electrical Repair San Diego Electrician's take on sudden surges in electric bills

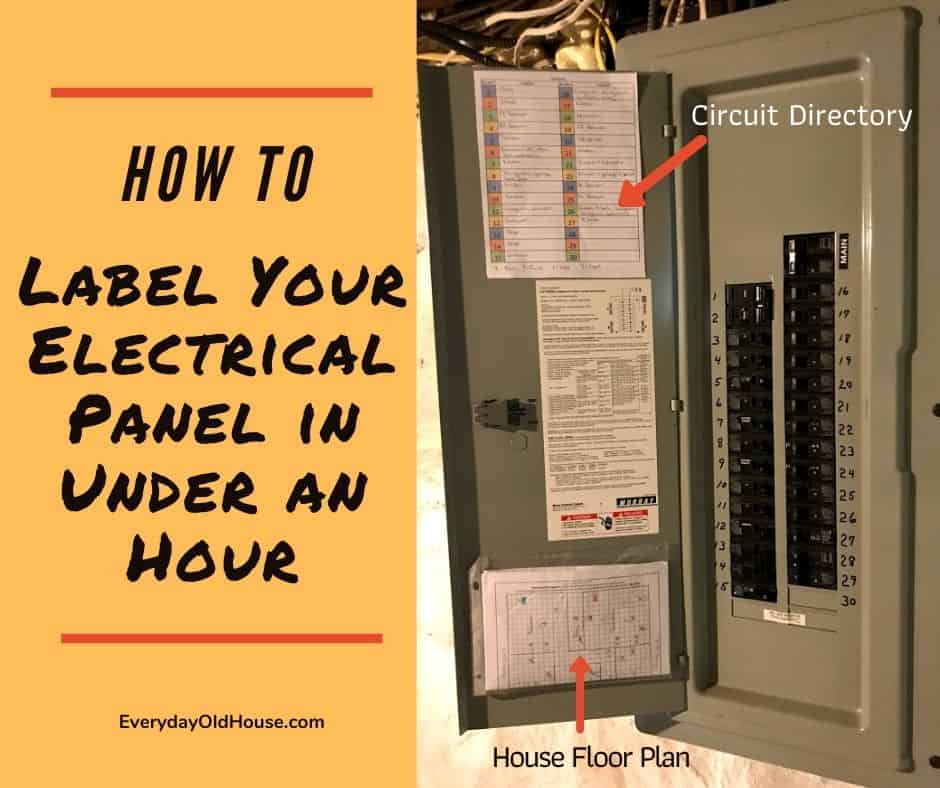

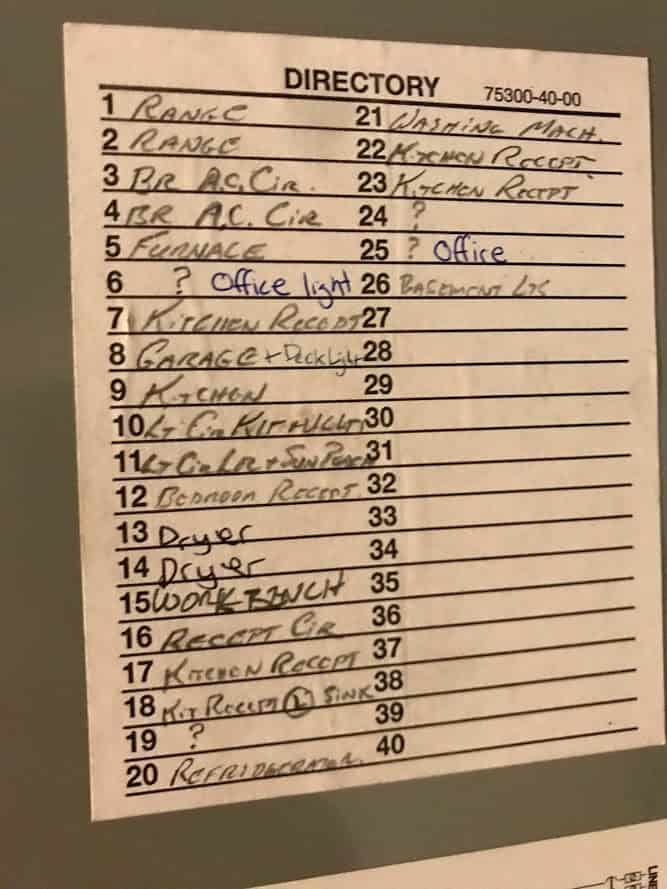

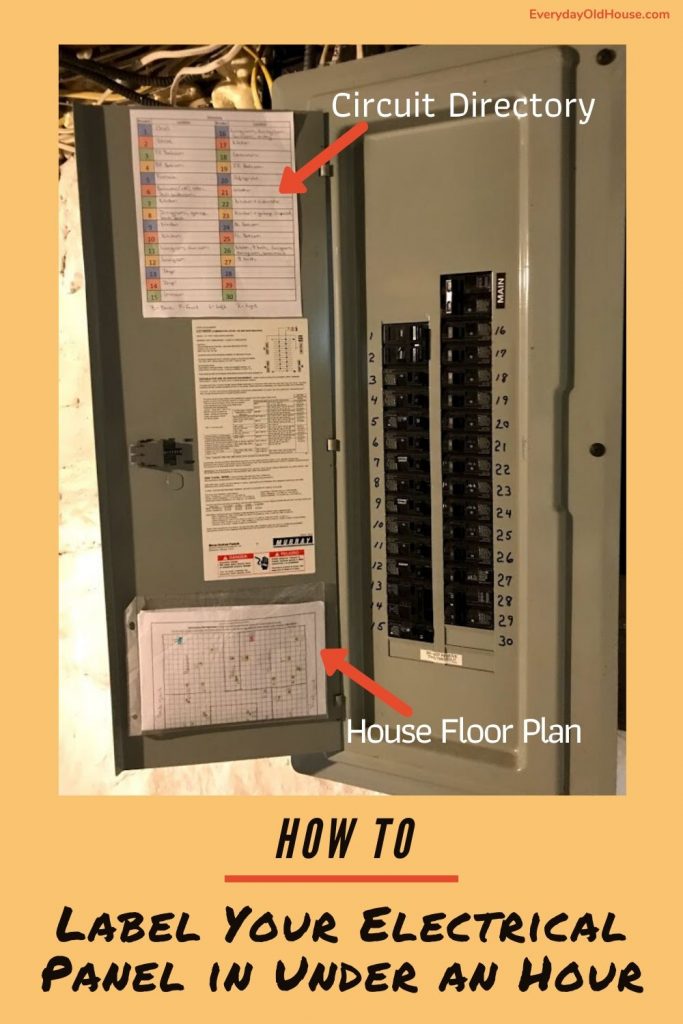

How to Label an Electrical Service Panel | Hunker Assign each circuit breaker a number inside the panel, starting with #1 at the top left. It's best if the number sequence proceeds down the left side to the bottom and continues from the top right to the bottom right. Write each number with a felt tip marker on a 1-inch square sticky label and affix each label next to the breaker it references.

PDF Electrical Panel Requirements - Wisconsin Healthcare Engineering ... Electrical Panel Requirements 22 1. Electrical Panel Requirements (Labeling, Clearances, Protection, Act) 2. Other Electrical Code Citations (Extension Cords & Power Strips, Open Boxes, Fire Stopping, Arc Flash) © 2020 LLSC Heather Lauzon Werner 23 Labeling © 2020 LLSC Overcurrent devices or disconnecting devices:

Electrical Panel Labels | Family Handyman The identification must be included in a circuit directory that is located on the face or inside of the panel door. The circuit directory must be durable enough to withstand the environment in which it is located. Each label identification must contain a degree of detail that distinguishes it from all other circuits.

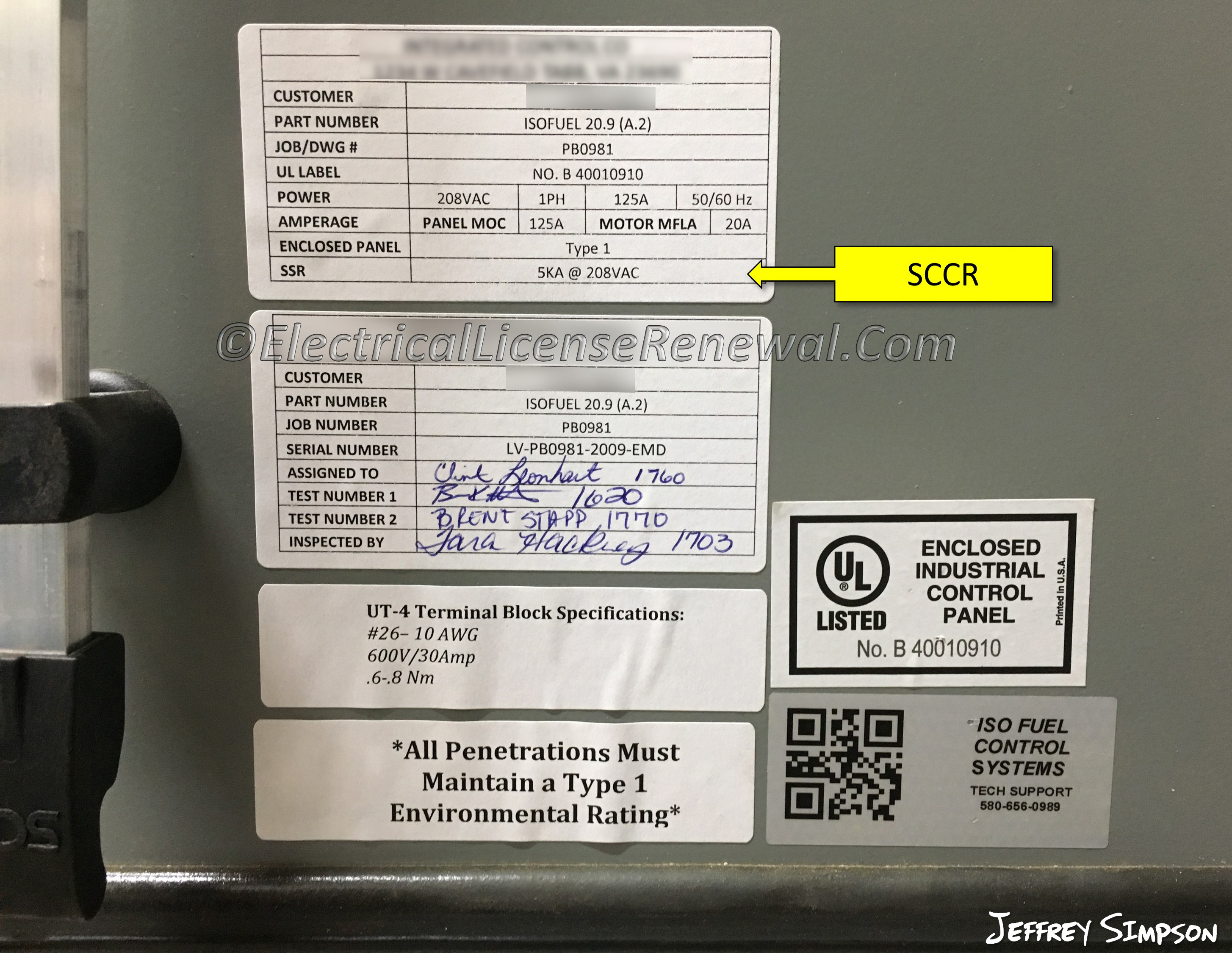

Strategies for electrical labeling and documentation NFPA 79-2015: Electrical Standard for Industrial Machinery, Article 700.5 (E), requires labeling of panel short-circuit current rating (SCCR) based on OCPD settings used. Periodic review of existing OCPD settings is a good idea to maintain a safe electrical system.

Electrical Panel Compliance with Floor Marking - Graphic Products The width of the space in front of an electrical panel must be the width of the equipment or 30 inches, whichever is wider. The working space must allow for a hinged panel or equipment door to open at a 90° angle. The vertical space must extend from the grade, floor, or platform immediately in front of the electrical panel to either:

NEC + OSHA Electrical Panel Clearance Requirements This means you cannot place machinery or other equipment in the space around an electrical panel without making sure that it meets the NEC working clearance requirements. In general, any electrical panel that has 0 to 150 volts going through it needs to have at least 36'' of clearance around it. Panels with 151 to 600 volts should have 42 ...

NFPA 70E minimum labeling for panels | Electrician Talk Article 130.5 (C) Equipment Labeling. Electrical equipment such as switchboards, panelboards, industrial control panels, meter socket enclosures, and motor control centers that are likely to require examination, adjustment, servicing, or maintenance while energized shall be field marked with a label containing all the following information:

How To Label An Electrical Panel (The Right Way) in Your Tigard Oregon Home 2020 NEC Article 408.4 (A) states: "Every circuit and circuit modification shall be legibly identified as to its clear, evident, and specific purpose or use. The identification shall include an approved degree of detail that allows each circuit to be distinguished from all others.

NEC 110 Labeling Requirements | Graphic Products NEC Article 110 includes new labeling requirements. There are three parts to the available fault current labels for equipment rating purposes. Learn more! Keeping You Safe Since 1970 ... that should not come in contact with electrical equipment.You can fulfill your labeling requirements and create custom electrical labels with ...

What are the Requirements for Electrical Panel Labeling? The labels that are required for electrical boxes will usually focus on two things. The first is going to be safety related labels. This could be something like a label to indicate how many volts are on a specific breaker, for example. You will also need to have the breakers labeled to indicate what area they will cut power to if turned off.

OCWR - Electrical Panel Safety For equipment operating at 600 volts, nominal or less to ground, electrical panels must have a minimum of three feet of clearance in front of the panel and a minimum clearance width of 2.5 feet or the width of the equipment, whichever is greater.

PDF Electrical Electrical Identification Basis of Design Label conduit at all wall penetrations and connections to all panels, junction boxes, and equipment served. 3. Use a black indelible marker and hand print label in a clear workmanlike manner, or use stencil and black paint to provide a clearly legible label. C. Empty conduits 1.

A related requirement is NEC 210.5 (C) (3), which defines the labeling of conductors originating within each branch circuit panelboard or similar branch circuit distribution equipment. The wires need to either be color coded or marked with color-coded labels. Example: A = black, B = red, and C = blue (neutral is white)

:max_bytes(150000):strip_icc()/how-to-wire-an-electrical-panel-1152762-11-ce4617ba201648959f532163cf32b8c6.jpg)

Post a Comment for "38 electrical panel labeling standards"